How To Fix a Photoelectric Sensor That Does Not Work

Introduction

In outdoor lighting, where our dedication to energy efficiency meets the challenges of the unpredictable, one necessary element often takes center stage – the photoelectric sensor. It’s not uncommon to encounter a scenario where this vital component isn’t quite pulling its weight.

This is an unexpected situation many of us in the lighting industry have faced – the sensor just not doing its job as anticipated, losing its responsiveness to light alterations, or being stuck in a perpetual state of confusion. Figuring out how to fix a non-responsive photoelectric sensor becomes a priority.

In this article, we’ll delve into the complexities of sensor functionality, exploring strategies to revive these essential components. Join me in shedding light on the methods and insights for fixing a photoelectric sensor and creating a dependable and efficient outdoor lighting solution.

What Are Photoelectric Sensors?

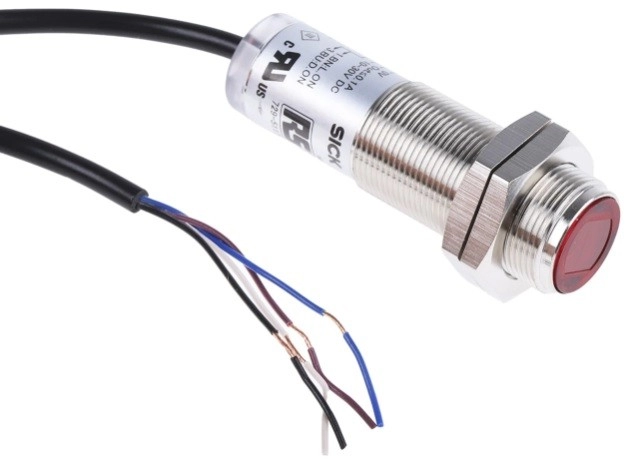

Photoelectric sensors leverage the photoelectric effect – the emission of electrons from a material when illuminated by light. These sensors consist of a light source (usually an LED), a receiver (photodiode or phototransistor), and associated electronics. The emitted light interacts with the target object, and the receiver then detects the reflected or transmitted light.

They work by using light beams to detect the presence or absence of an object. When something interrupts the light beam, it triggers a response – like turning on the lights in a hallway when someone walks by.

Photoelectric sensors operate on the principle of emitting a light beam and then detecting the light that reflects off or passes through an object. There are three main types: through-beam, retroreflective, and diffuse.

Through-beam Sensors

In this configuration, a separate transmitter and receiver are placed opposite each other. Detection occurs when an object interrupts the direct path between them, causing a change in received light intensity. Essentially, there’s a transmitter on one side and a receiver on the other. The object is detected when it interrupts the beam between them.

Retroreflective Sensors

Here, the transmitter and receiver are housed together, with a reflector placed at a certain distance. The sensor detects an object when it disrupts the reflected light path between the sensor and the reflector.

Diffuse Sensors

These sensors combine the transmitter and receiver in one housing. The light emitted reflects off the object and goes back to the sensor. If the intensity changes due to an object’s presence, the sensor registers it. Object detection is based on the changes in received light intensity caused by the object.

In terms of applications, these sensors are practically everywhere, from industrial automation to everyday gadgets. In factories, they help in material handling by detecting objects on conveyor belts. They’re also widely used in elevators, security systems, and even your smartphones for proximity sensing.

Photoelectric sensors play a crucial role in various industries, offering a versatile solution for detecting and monitoring objects. Their importance lies in their ability to provide reliable and efficient sensing in a wide range of applications.

Another significant aspect of photoelectric sensors is their precision in object detection. Unlike some traditional sensors, these devices can detect objects regardless of their material, color, or surface characteristics. This versatility makes them indispensable in manufacturing processes where accurate object detection is paramount.

In the era of automation, photoelectric sensors contribute significantly to improving efficiency. They play a vital role in automated processes by ensuring accurate object positioning, sorting, and quality control. This level of precision minimizes errors, reduces downtime, and ultimately enhances overall production efficiency.

Just like anything else, photoelectric sensors have their pros and cons. On the plus side, they’re reliable, fast, and versatile. They can handle various materials and are unaffected by color. However, they can be sensitive to environmental conditions like dust or ambient light.

Common Issues with Photoelectric Sensors

While versatile, photoelectric sensors are susceptible to various technical issues that can impact their performance. Some of these problems include:

Sensitivity Challenges

One common issue arises from sensitivity fluctuations. External factors such as dust, moisture, and temperature variations can compromise the sensor’s ability to accurately detect changes in light, leading to unreliable readings.

Alignment Issues

Precise alignment is paramount for these sensors to function optimally. Misalignment between the emitter and receiver can result in inaccurate readings, creating a need for meticulous positioning to prevent operational discrepancies.

Ambient Light Interference

Excessive ambient light poses a significant threat to photoelectric sensors. When ambient light surpasses the sensor’s designed thresholds, it may erroneously interpret this additional light as the intended signal, causing confusion and potential errors.

Cross-Talk Disturbances

Cross-talk, akin to signal interference, occurs when signals from one sensor interfere with neighboring sensors. This interference can distort readings, introducing inaccuracies and complicating the sensor network’s overall performance.

Power Supply Complications

Power-related issues are often overlooked but can profoundly impact sensor functionality. Inadequate power supply can lead to suboptimal performance, emphasizing the importance of monitoring and maintaining a consistent power source for sustained sensor efficiency.

While photoelectric sensors offer valuable functionality, understanding and addressing sensitivity, alignment, ambient light, cross-talk, and power supply issues are essential for maintaining their reliability and ensuring accurate data acquisition in diverse applications.

Step-by-Step Troubleshooting Guide

If your photoelectric sensor is malfunctioning, following this step-by-step guide will help you fix it. The guide delves into the nuanced troubleshooting of photoelectric sensors, addressing technical intricacies associated with their operational anomalies. The aim is to systematically diagnose and rectify issues that may impede optimal sensor performance.

Step 1: Power Check

Initiate the troubleshooting process by conducting a voltage and current analysis to ensure the photoelectric sensor receives the specified power supply within the designated tolerances. Use precision measuring instruments for accurate readings.

Step 2: Clean the Internal Components

Perform an optical inspection of the sensor’s emitter and receiver components. Utilize a high-resolution microscope to identify and eliminate microscopic contaminants, ensuring an unobstructed optical path.

Step 3: Check the Alignment

Utilize laser alignment tools and precision measuring instruments to assess and correct angular misalignment between the photoelectric sensor and reflectors. Implement trigonometric calculations to ensure precise alignment within specified angular tolerances.

Step 4: Test the Cables

Employ cable testers and multimeters to analyze the integrity of the sensor’s cabling infrastructure. Evaluate signal continuity, insulation resistance, and shielding effectiveness to identify and rectify any cable-related issues.

Step 5: Environment Check

Conduct a thorough environmental analysis using specialized sensors and data loggers. Monitor temperature, humidity, and ambient light levels to identify potential environmental factors impacting sensor performance. Implement corrective measures based on collected data.

Step 6: Calibration

Refer to the sensor’s technical documentation to execute a recalibration procedure. Utilize advanced calibration equipment such as spectrometers and precision alignment tools to ensure the sensor’s output aligns with specified calibration parameters.

This meticulously crafted technical guide offers a systematic approach to troubleshooting common photoelectric sensor issues. However, consider exploring the expertise and resources available at Chiswear for further technical insights or assistance.

Summary

In rectifying a non-functional photoelectric sensor, a methodical approach to troubleshooting becomes paramount. Initiate the diagnostic process by scrutinizing power supply integrity and confirming precise sensor alignment. Proceed to conduct a meticulous examination for potential obstructions or environmental influences that may impede sensor functionality. Delve into the intricacies of sensitivity settings, ensuring optimal calibration aligned with specific application requirements. Through this systematic troubleshooting method, you can fix your photoelectric sensor.